Our PROJECTS

Delivering Excellence in Every Project

Projects that define Quality and Innovation.

Driving progress through Engineering Mastery.

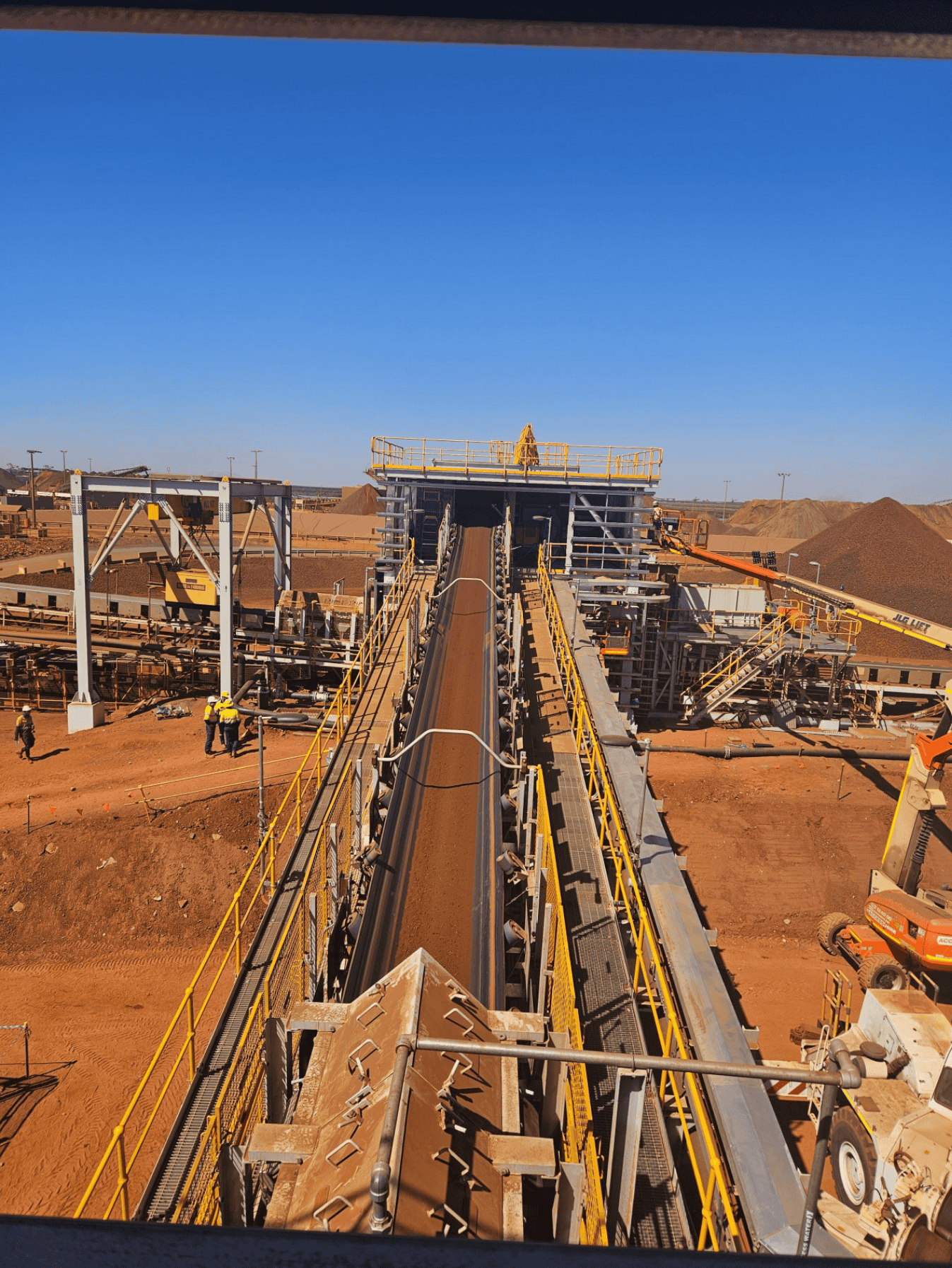

UTAH POINT, STOCKYARD #2 UPGRADE

DHHI & Atlas Iron

To support Atlas Iron’s growing operations, the Utah Point Stockyard #2 was upgraded to support a 12Mtpa throughput increase.

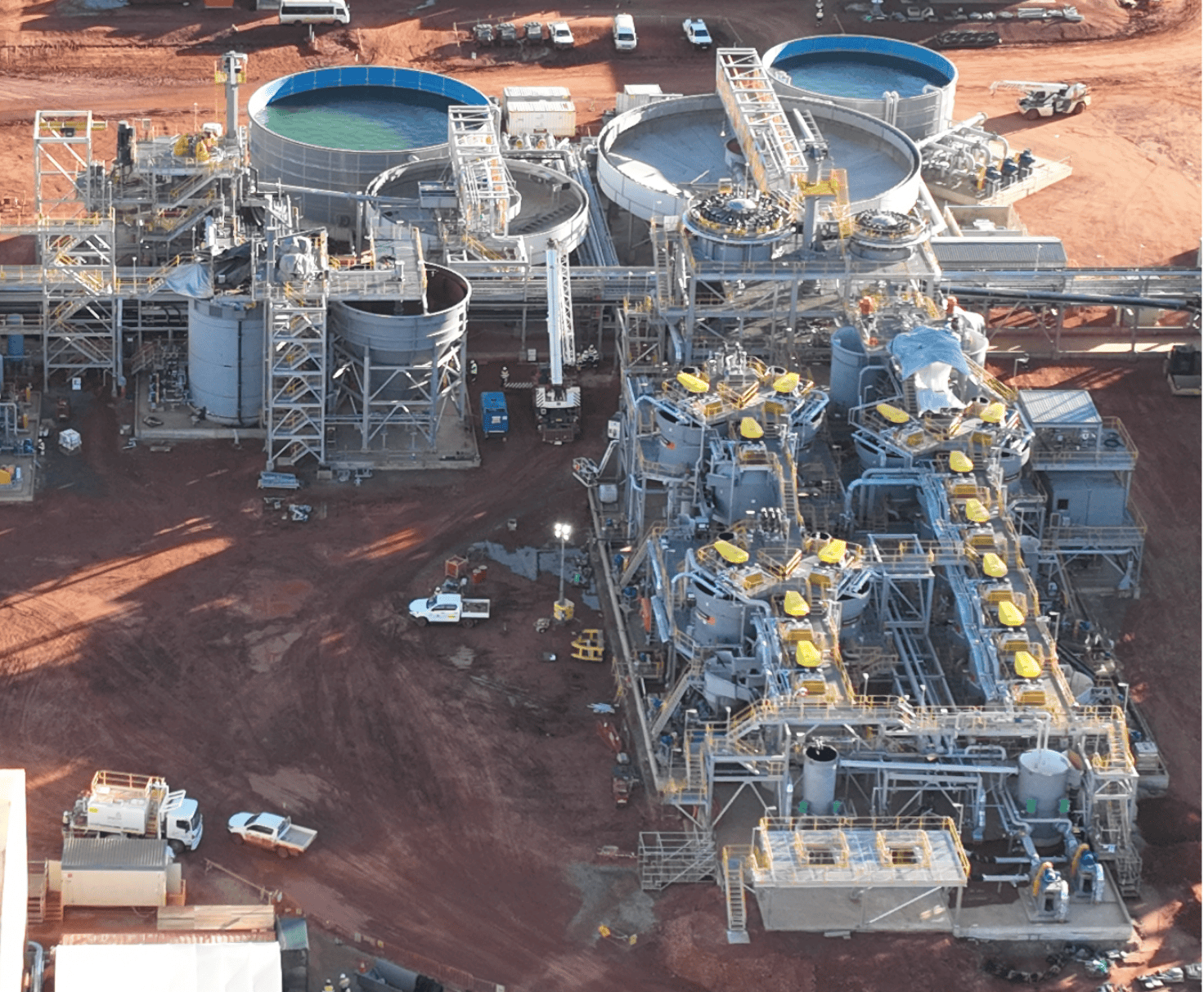

BUTCHERBIRD EXPANSION

Element 25

Element 25 is expanding their Butcherbird Operations to increase the production of manganese concentrate at the company’s tenement located in the southern Pilbara region of Western Australia.

MESA J – PP2 & TLO

RIO TINTO & UGL Limited

Rio Tinto’s Robe Valley Sustaining (RVS) Project, included two major developments to its existing Mesa J hub.

KATHLEEN VALLEY

Liontown Resources

The Project is a new Lithium-Tantalum Processing Facility, comprising of an open pit and underground mine, a dry plant, wet plant, hybrid power generation facilities, accommodation village and associated non-process infrastructure.

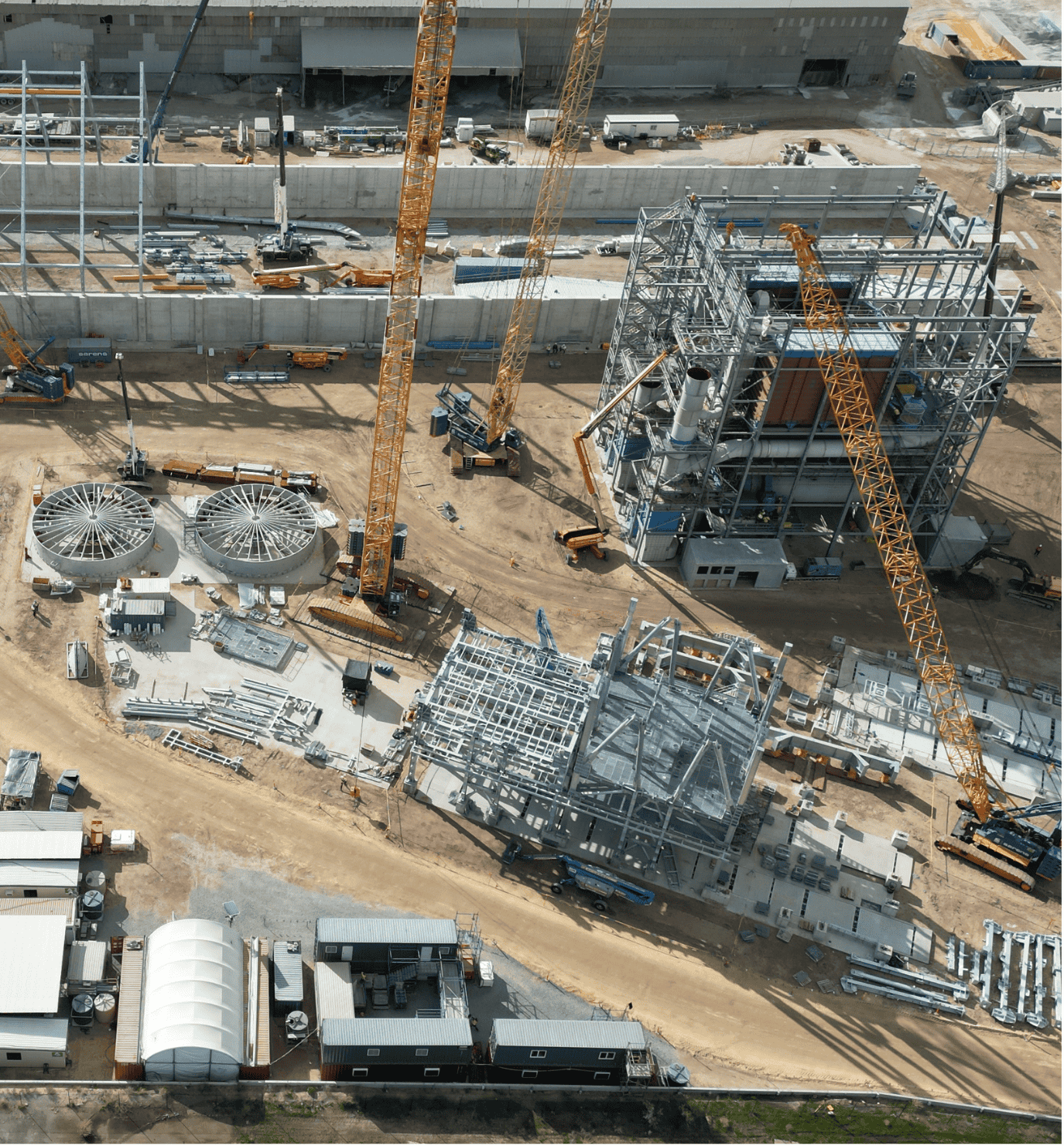

KWINANA UPGRADE

Cockburn Cement

The KWUP Project in Kwinana, WA, is WA’s largest cement manufacturing facility, featuring a 110,000-tonne storage shed, two 100-tonne/hour ball mills, and six 3,200-tonne silos with truck loading.

APRON FEEDER SHAFT REMOVAL TROLLEY

BHP Billiton & UGL Limited

UGL were engaged for a major shutdown at BHP Nelson Point in Port Hedland. Works included the upgrade and refurbishment of Apron Feeders AF31 & AF32. The biggest unknown for the job was how to changeout the 4 off Apron Feeder drive shafts.

THOMAS YARD RSM WORKSHOP EXTENSION

Fortescue Metal Group (FMG)

Design, Construct (D&C) and Commission of an extension (2000m2) to the Rolling Stock Maintenance (RSM) Facility at FMG’s Thomas Yard.

BINDULI NORTH HEAP LEACH

Norton Gold Fields (Zijin Mining)

The Norton Gold Field Binduli North Heap Leach Project is a specialized gold processing plant designed for the efficient extraction of gold from low-grade ore.

SUSTAINING CAPITAL, SHUTDOWN, AND MAINTENANCE FACILITIES

Pilbara Minerals (PLS)

Pilbara Minerals is expanding with three new facilities: an 80-person office, two 40ft workshops, and a sustaining capital cribbing facility.

UNDERFLOOR WHEEL LATHE

Fortescue Metal Group (FMG)

The project included engineering, supply and replacement of the Underfloor Wheel Lathe at FMG’s Thomas Yard (Rolling Stock Maintenance Facility). The existing lathe was removed and replaced with an upgraded 45t axle capacity lathe to future proof the FMG RSM network.